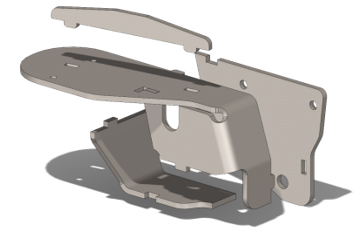

A costly part of the manufacturing process is creating fixtures, so many designers are now turning to self-fixturing, design techniques to reduce assembly and set-up costs in the manufacturing process. SOLIDWORKS 2018 introduces a powerful Tab and slot tool to automate this design step.

A costly part of the manufacturing process is creating fixtures, so many designers are now turning to self-fixturing, design techniques to reduce assembly and set-up costs in the manufacturing process. SOLIDWORKS 2018 introduces a powerful Tab and slot tool to automate this design step.

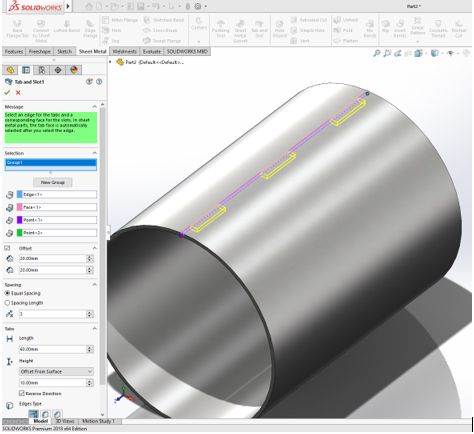

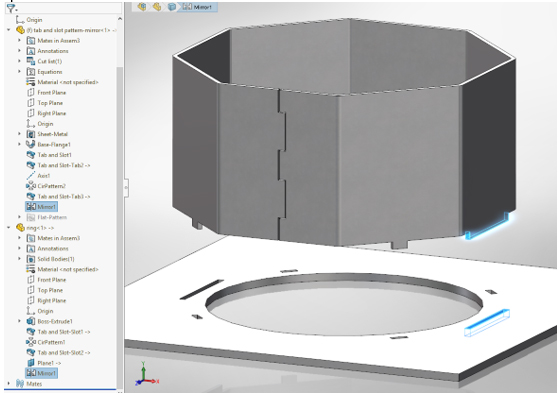

Tab and slot can be created on parts in an assembly, a single part, or a multibody part. You start by choosing an edge to define the tab, and a face to define where the slot where will terminate. Offsets can be applied to control the tab distance from the ends. Spacing can be defined equally among a given number of instances or by a defined length. The length of each tab can easily be specified, and the height can be a blind value, or up-to or offset-from the selected surface.

Corner treatments, such as fillets and chamfers can be applied to the tabs and their size can be specified. The clearance between the slot and tab can be defined as well and SOLIDWORKS creates features in both components to meet these specifications.

These tab and slot features are fully editable, for instance, an additional tab and slot can be added on the side by adding a new group to the definition.

The new tab and slot feature not only reduces design time by automating the creation of these features but reduces manufacturing costs by minimizing the need to build expensive fixtures that can delay manufacturing.